On the HS2 Enabling Works Contract-South, the location of the demolition work involved in the London leg of Phase one made it imperative for the John F Hunt team to reduce the impact of noise, vibration and air quality on the local community.

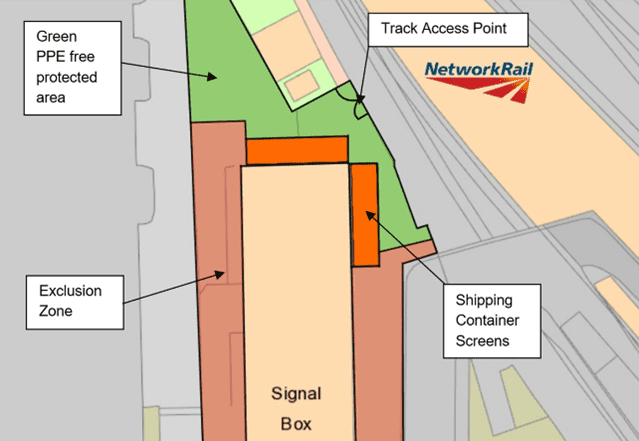

The Euston Power Signal Box (PSB) was located adjacent to platform 16 of Euston Station, with a Network Rail (NR) maintenance point situated 5m from the North of the building.

Shipping Container Screen

Due to these restrictions, John F Hunt proposed a shipping container screen, creating a solid barrier between the demolition works and the NwR maintenance access point.

This ground-breaking engineering solution mitigated against uncontrolled collapse, debris release, noise, and dust, as well as eliminating working at height issues and protecting Network Rail assets and staff.

Shipping Container Construction

- Two independent screens, constructed from 12 shipping containers, 2 units wide and 6 units tall.

- Each stack was secured to a reinforced concrete foundation base, using corner twist-locks, bridge clamps and freight cross bracing.

- The containers were weighted using water-filled IBC’s as kentiledge.

- The interfacing corner of the containers was closed with Monarflex sheeting.

- Installation of the two 12 stack containers took 4 days, using a mobile crane on the west side of the building and a crawler crane on the eastern side.

- A single width container screen was installed for the south of the building, eliminating the need for a lane closure whilst still providing protection against debris, dust, and collapse.

Benefits

- Independence of structure not being tied to the building, enabling full height to be retained until the demolition was cleared.

- Increased Design Load catered for safety elements in high winds and in case of debris impact

- No progressive collapse elements, unlike scaffold poles

- Excellent debris retention ensuring no material left the demolition area

- Reduced working at height for all operatives by 3,400 hours

- Limited execution risk, with 11,000 components being reduced to 330

- 47% reduction in programme duration with no cost increase

- 28t of carbon dioxide elimination

Conclusion

The container screen innovation has set a new standard for demolition when in close proximity to Network Rail assets and access.

The robustness and independence of the screens enabled demolition works to be completed ahead of programme, whilst maintaining safe, 24/7 access to Network Rail, just 5m from the point of demolition.

Demolition Curtain

In a further effort to reduce the impact of our works where the containers could not be used, the John F Hunt team used a thick rubber curtain, connected to a spreader beam which was suspended from a remote-controlled crane, to retain debris, dust and noise during demolition.

Benefits

- quick deployment, with flexibility in positioning around the structure

- Reduced area footprint, allowing use in locations of restricted access

- eliminates working at height

Remote Crane Operation

A line-of-sight controller was used to provide full remote control of the crane, the operator monitoring all parameters, including wind speed, from the device, enabling instant adjustment.

Another key challenge was how to manage the volume of waste being produced through the demolition, due to the congested road network based primarily around Euston Station in the London Borough of Camden.

Crushing On-Site

Despite being constrained on all sides, with very little room for manoeuvre, John F Hunt delivered a top-down solution that crushed more than 70% of the material on the site’s footprint. This was then used to create temporary vehicle access ramps, crane mats and haul roads, as well as backfill for structures and platforms to facilitate the main works civils contract.

- 175,000 tonnes of demolition arisings crushed on site

- saving more than 1,500 tonnes of CO2 equivalent (CO2e)

- No waste removal or material delivery, saving nearly £5m.

- saved 39,000 vehicle movements significantly reducing impacts on local roads and air quality.

- Working with HS2 and the Environment Agency enabled John F Hunt to carry out multiple work package areas, treating them as a ‘single site’, facilitating the transfer, storage, and re-use of recovered materials.

In an effort to become a paperless site and further lower the carbon used, Euston became a fully digital project.

- 28,000 A4 pages saved

- All subcontractor staff access latest information via tablet

- Collaborative touch screens and rolling office display screens

- QR tagged plant and tools

- Regular drone surveys were carried out as demolition progresses

For more information on John F Hunt, or to contact the team for your project, call now on 01375 366700, email at info@johnfhunt.co.uk or fill in the contact form at the bottom of the page https://www.johnfhunt.co.uk/group-services