A new client contracted BD Nuclear to create six openings on the ground floor of a three-storey retail building on Portsmouth’s main high street.

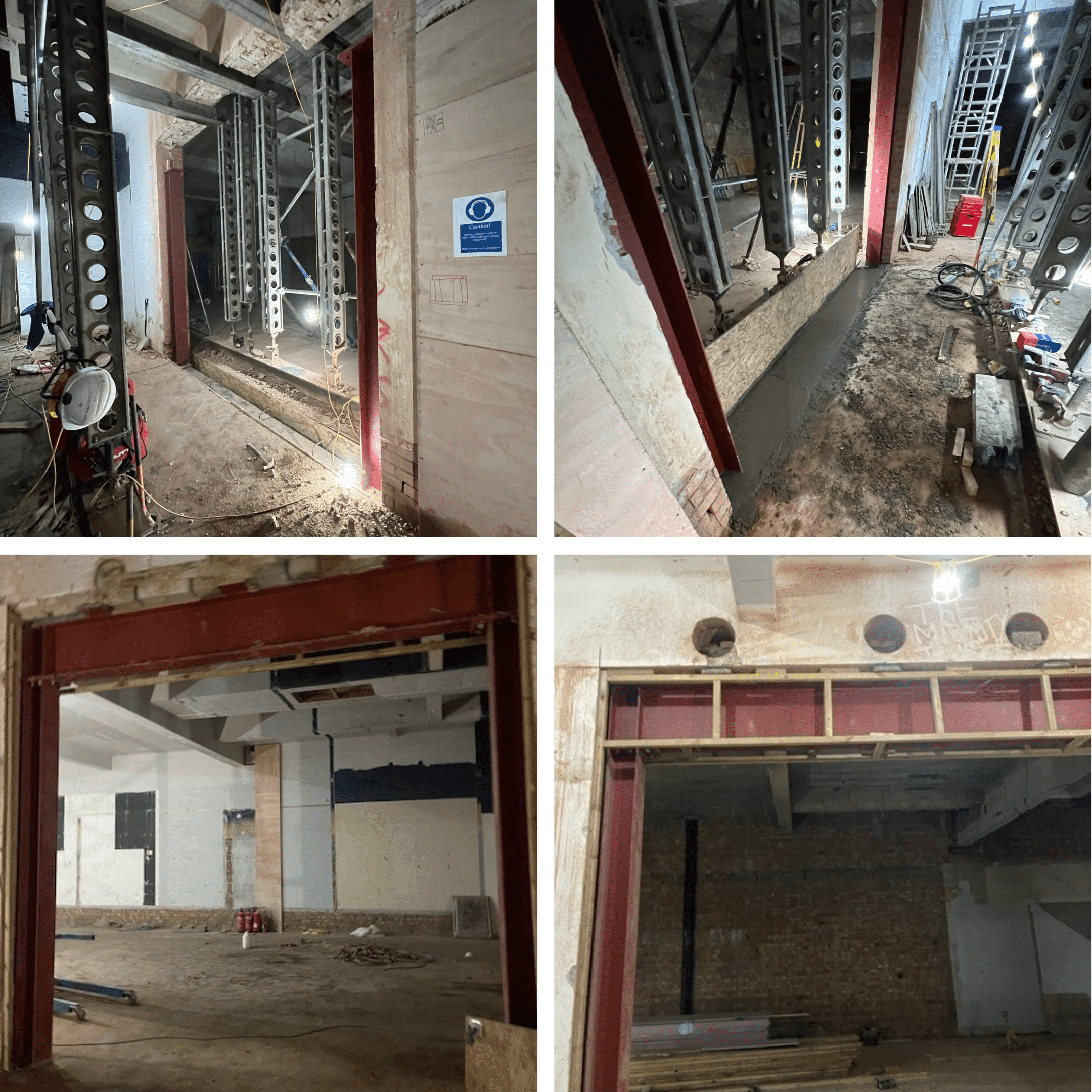

We cut and broke out six 3.7m x 4.2m openings through a 500mm thick wall and installed a steel frame ‘goal post’ arrangement with a below-ground beam which was concreted level with the floor slab, and this is how we did it.

The sequence of works started with diamond drilling 18×300mm holes through the brickwork wall. This allowed the Mabey propping system and needles to be passed through the walls and propped, with four jacking props on each side and spreader beams to distribute the load on the suspended pot and beam floor.

The follow-on process required the top and two sides to be cut using a track saw, ready to break out the openings down to ground level.

We then diamond drilled down a further 700mm each side of the opening and broke out the rest of the wall 700mm down from the top of the ground floor slab. The waste material was safely cleared in stages to a laydown area outside the building, which was removed by grab lorries for recycling.

When the area was clear, we installed the steel frame and shuttering was erected around the lower beam that was set 160mm below ground floor level. Steel mesh was then added, and the beam was concreted level with the ground floor slab.

The top steels were dry packed, and after 24 hours the propping system was dismantled, and needle holes bricked up. We carried out two of these openings at the same time, with the process being repeated for the remaining four openings.

Another full-height door opening was cut into the exterior wall with an additional brick peer built to support structural lintels.

All works were completed on time, which resulted in a happy client and two additional jobs quoted.

Well done BD Nuclear!