Page 78 - PowerPoint Presentation

P. 78

Let’s all

DIAMOND DRILLING get home safely,

every day

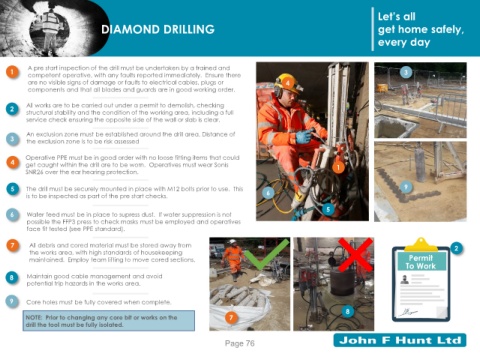

1 A pre start inspection of the drill must be undertaken by a trained and 3

competent operative, with any faults reported immediately. Ensure there

are no visible signs of damage or faults to electrical cables, plugs or 4

components and that all blades and guards are in good working order.

2 All works are to be carried out under a permit to demolish, checking

structural stability and the condition of the working area, including a full

service check ensuring the opposite side of the wall or slab is clear.

An exclusion zone must be established around the drill area. Distance of

3 the exclusion zone is to be risk assessed

Operative PPE must be in good order with no loose fitting items that could

4 get caught within the drill are to be worn. Operatives must wear Sonis

SNR26 over the ear hearing protection. 1

5 The drill must be securely mounted in place with M12 bolts prior to use. This 9

is to be inspected as part of the pre start checks. 6

5

6 Water feed must be in place to supress dust. If water suppression is not

possible the FFP3 press to check masks must be employed and operatives

face fit tested (see PPE standard).

7 All debris and cored material must be stored away from 2

the works area, with high standards of housekeeping

Permits

maintained. Employ team lifting to move cored sections. Permit

To Work

to Work

8 Maintain good cable management and avoid

potential trip hazards in the works area.

9 Core holes must be fully covered when complete.

8

NOTE: Prior to changing any core bit or works on the 7

drill the tool must be fully isolated.

Page 76