Page 38 - Visual Guidance Handbook

P. 38

Let’s all

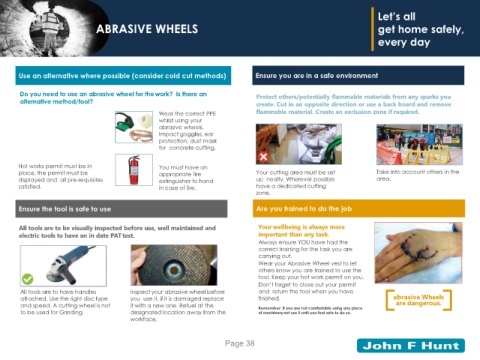

ABRASIVE WHEELS get home safely,

every day

Use an alternative where possible (consider cold cut methods) Ensure you are in a safe environment

Do you need to use an abrasive wheel for thework? Is there an Protect others/potentially flammable materials from any sparks you

alternative method/tool?

create. Cut in an opposite direction or use a back board and remove

Wear the correct PPE flammable material. Create an exclusion zone if required.

whilst using your

abrasive wheels.

Impact goggles, ear

protection, dust mask

for concrete cutting.

Hot works permit must be in You must have an

place, the permit must be appropriate fire Your cutting area must be set Take into account others in the

displayed and all pre-requisites extinguisher to hand up neatly. Wherever possible area.

satisfied. in case of fire. have a dedicated cutting

zone.

Ensure the tool is safe to use Are you trained to do the job

All tools are to be visually inspected before use, well maintained and Your wellbeing is always more

electric tools to have an in date PATtest. important than any task.

Always ensure YOU have had the

correct training for the task you are

carrying out.

Wear your Abrasive Wheel vest to let

others know you are trained to use the

tool. Keep your hot work permit on you.

Don’t forget to close out your permit

All tools are to have handles Inspect your abrasive wheel before and return the tool when you have

attached. Use the right disc type you use it, if it is damaged replace finished. abrasive Wheels

and speed. A cutting wheel is not it with a new one. Refuel at the Remember: if you are not comfortable using any piece are dangerous.

to be used for Grinding. designated location away from the of machinerynot use it until you feel safe to do so.

workface.

Page 38