Page 9 - Visual Guidance Handbook

P. 9

Let’s all

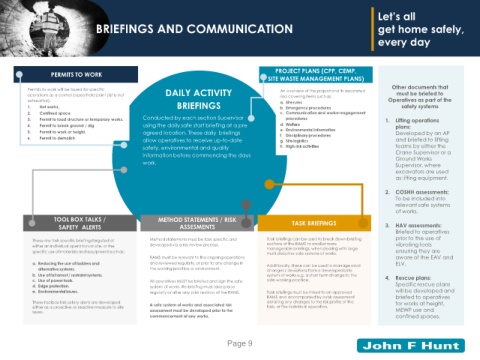

BRIEFINGS AND COMMUNICATION get home safely,

every day

PROJECT PLANS (CPP, CEMP,

PERMITS TO WORK

SITE WASTE MANAGEMENT PLANS)

Other documents that

Permits to work will be issued for specific DAILY ACTIVITY An overview of the project and its associated

operations as a control based hold point (list is not risks covering items suchas: must be briefed to

exhaustive). a. Site rules Operatives as part of the

1. Hot works, BRIEFINGS b. Emergency procedures safety systems

2. Confined space c. Communication and workerengagement

3. Permit to load structure or temporary works. Conducted by each section Supervisor procedures 1. Lifting operations

4. Permit to break ground / dig using the daily safe start briefing at a pre d. Welfare plans:

5. Permit to work at height. agreed location. These daily briefings e. Environmental information Developed by an AP

6. Permit to demolish allow operatives to receive up-to-date f. Disciplinary procedures and briefed to lifting

g. Site logistics

safety, environmental and quality h. High riskactivities teams by either the

information before commencing the days Crane Supervisor or a

Ground Works

work. Supervisor, where

excavators are used

as lifting equipment.

2. COSHH assessments:

To be included into

relevant safe systems

of works.

TOOL BOX TALKS / METHOD STATEMENTS / RISK TASK BRIEFINGS

SAFETY ALERTS ASSESMENTS 3. HAV assessments:

Briefed to operatives

These are task specific briefingstargeted at Method statements must be task specific and Task briefings can be used to break down briefing prior to the use of

either an individual operation on site, or the developed via a risk review process. sections of the RAMS to smaller more vibrating tools

manageable briefings, when dealing with large

specific use of materials and equipment such as: multi discipline safe systems of works. ensuring they are

RAMS must be relevant to the ongoing operations aware of the EAV and

a. Reducing the use of ladders and and reviewed regularly, or prior to any change in Additionally, these can be used to manage small ELV.

alternative systems. the working practice or environment. changes / deviations from a developed safe

b. Use of fall arrest / restraint systems. system of works e.g. a short term change to the 4. Rescue plans:

c. Use of powertools. All operatives MUST be briefed and sign the safe safe working practice.

d. Edge protection. system of works. Re-briefing must take place Specific rescue plans

e. Environmental issues. regularly or after any prior revision of the RAMS. Task briefings must be linked to an approved will be developed and

RAMS and accompanied by a risk assessment briefed to operatives

These toolbox talk safety alerts are developed detailing any changes to the risk profile of the for works at height,

either as a proactive or reactive measure to site A safe system of works and associated risk task, or the individual operation. MEWP use and

issues. assessment must be developed prior to the

commencement of any works. confined spaces.

Page 9