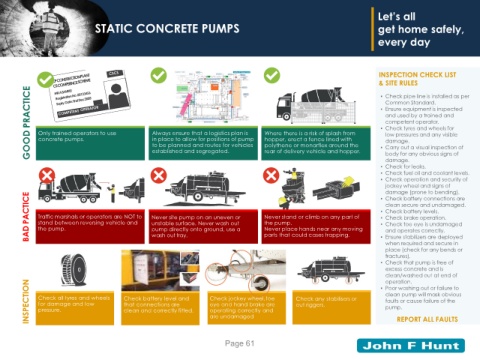

Page 61 - Visual Guidance Handbook

P. 61

Let’s all

STATIC CONCRETE PUMPS get home safely,

every day

INSPECTION CHECK LIST

& SITE RULES

PRACTICE ▪ Check pipe line is installed as per

Common Standard.

▪ Ensure equipment is inspected

and used by a trained and

competent operator.

GOOD Only trained operators to use Always ensure that a logistics plan is Where there is a risk of splash from ▪ Check tyres and wheels for

low pressures and any visible

in place to allow for positions of pump

concrete pumps.

hopper, erect a fence lined with

damage.

polythene or monarflex around the

to be planned and routes for vehicles

▪ Carry out a visual inspection of

established and segregated.

rear of delivery vehicle and hopper.

body for any obvious signs of

damage.

▪ Check for leaks.

▪ Check fuel oil and coolant levels.

▪ Check operation and security of

jockey wheel and signs of

damage (prone to bending).

PACTICE Traffic marshals or operators are NOT to Never site pump on an uneven or Never stand or climb on any part of ▪ Check battery levels.

▪ Check battery connections are

clean secure and undamaged.

▪ Check brake operation.

the pump.

Never place hands near any moving

pump directly onto ground, use a

BAD stand between reversing vehicle and unstable surface. Never wash out the pump. ▪ Check toe eye is undamaged

and operates correctly.

wash outtray.

parts that could cases trapping.

▪ Ensure stabilizers are deployed

when required and secure in

place (check for any bends or

fractures).

▪ Check that pump is free of

excess concrete and is

clean/washed out at end of

operation.

INSPECTION Check all tyres and wheels Check battery level and Check jockey wheel,toe Check any stabilisers or clean pump will mask obvious

▪ Poor washing out or failure to

faults or cause failure of the

for damage and low

eye and hand brake are

that connections are

out riggers.

pump.

pressure.

clean and correctly fitted.

operating correctly and

are undamaged

REPORT ALL FAULTS

Page 61