Page 63 - Visual Guidance Handbook

P. 63

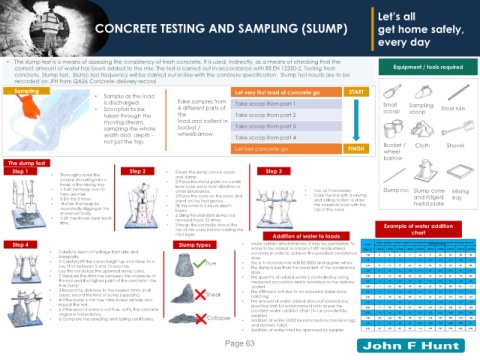

Let’s all

CONCRETE TESTING AND SAMPLING (SLUMP) get home safely,

every day

• The slump test is a means of assessing the consistency of fresh concrete. It is used, indirectly, as a means of checking that the

correct amount of water has been added to the mix. The test is carried out in accordance with BS EN 12350-2, Testing fresh Equipment / tools required

concrete. Slump test. Slump test frequency will be carried out in line with the concrete specification. Slump test results are to be

recorded on JFH form QA26 Concrete delivery record

Sampling Let very first load of concrete go START

• Sample as the load

is discharged. Take samples from Take scoop from part 1 Small Sampling

• Scoopfuls to be 4 different parts of scoop scoop Steel rule

taken through the the Take scoop from part 2

moving stream, load and collect in

sampling the whole bucket / Take scoop from part 3

width and depth - wheelbarrow. Take scoop from part 4

not just the top. Bucket / Shovel

Let last concrete go FINISH wheel- Cloth

barrow

The slump test

Step 1 Step 2 • Ensure the slump cone is clean Step 3

• Thoroughly remix the and damp.

sample shovelling into a • 2 Place the metal plate on a solid

heap in the mixing tray. level base away from vibration or

• 2 Turn the heap over to other disturbance. • Top up if necessary. Slump rod Slump cone Mixing

form another. • 3 Place the cone on the plate and • 2 Use the rod with a sawing

• 3 Do this 3 times. stand on the foot pieces. and rolling motion to strike and ridged tray

• Flatten the heap by • Fill the cone in 3 equal depth the concrete level with the metal plate

repeatedly digging in the layers. top of the cone

shovel vertically. • 2 Using the standard slump rod,

• 2 Lift the shovel clear each rod each layer 25 times.

time. • 3 Heap the concrete above the Example of water addition

top of the cone before rodding the chart

third layer Addition of water to loads

Step 4 Slump types • under certain circumstances, it may be permissible for

• Carefully clean off spillage from side and water to be added to a load of stiff ready-mixed

concrete in order to achieve the specified consistence

baseplate. class.

• 2 Carefully lift the cone straight up and clear, to a True • This is in accordance with BS 8500 and applies when:

count of between 5 and 10 seconds • the slump is less than the lower limit of the consistence

• Lay the rod across the upturned slump cone. class

• 2 Measure the distance between the underside of • the quantity of added water is controlled by being

the rod and the highest point of the concrete - the measured accurately and is recorded on the delivery

true slump. docket

• 3 Record this distance to the nearest 5mm. In all • the stiffness is not due to an excessive delay since

cases, record the kind of slump (opposite). Shear batching

• 4 If the slump is not true, take a new sample and • the amount of water added does not exceed any

repeat the test. specified limit for water:cement ratio as per the

• 5 If the second slump is not true, notify the concrete providers water addition chart (to be provided by

engineer immediately. supplier)

• 6 Complete the sampling and testing certificates. Collapse • Addition of water MUST be recorded on concrete logs

and delivery ticket.

• Addition of water must be approved by supplier

Page 63