Page 62 - Visual Guidance Handbook

P. 62

Let’s all

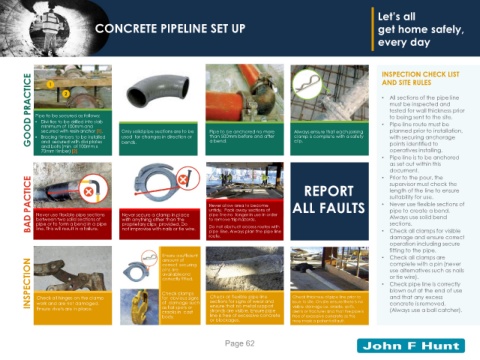

CONCRETE PIPELINE SET UP get home safely,

every day

INSPECTION CHECK LIST

PRACTICE 2 • All sections of the pipe line

AND SITE RULES

1

must be inspected and

tested for wall thickness prior

GOOD Pipe to be secured as follows: Only solid pipe sections are to be Pipe to be anchored no more Always ensure that each joining • to being sent to the site.

▪ Divi ties to be drilled into slab

Pipe line route must be

minimum of 100mm and

planned prior to installation,

secured with resinanchor [1].

with securing anchorage

used for changes in direction or

clamp is complete with a safety

than 500mm before and after

▪ Bracing timbers to be installed

a bend.

clip.

and secured with divi plates

and bolts (min of 100mm x

operatives installing.

70mm timber) [2]. bends. points identified to

• Pipe line is to be anchored

as set out within this

document.

Prior to the pour, the

•

PACTICE Never allow area to become ALL FAULTS • supervisor must check the

REPORT

length of the line to ensure

suitability for use.

Never use flexible sections of

pipe to create a bend.

untidy. Pack away sections of

BAD Never use flexible pipe sections Never secure a clamp in place pipe line no longer in use in order Always use solid bend

with anything other than the

between two solid sections of

to remove trip hazards.

sections.

pipe or to form a bend in a pipe

proprietaryclips provided. Do

Do not obstruct access routes with

line. This will result in a failure.

not improvise with nails or tie wire.

pipe line. Always plan the pipe line

route. • Check all clamps for visible

damage and ensure correct

operation including secure

fitting to the pipe.

Ensure a sufficient • Check all clamps are

amount of

INSPECTION Check all hinges on the clamp pins are Check all flexible pipe line Check thickness of pipe line prior to • use alternatives such as nails

complete with a pin (never

correct securing

availableand

or tie wire).

correctly fitted.

Check pipe line is correctly

blown out at the end of use

Check clamps

and that any excess

for obvious signs

of damage such

work and are not damaged.

ensure that no metal support

visible damage i.e. cracks, splits,

as flat spots or

(Always use a ball catcher).

Ensure rivets are in place.

strands are visible. Ensure pipe

cracks in cast sections for signs of wear and issue to site. On site ensure there is no concrete is removed.

dents or fractures and that the pipe is

body. line is free of excessive concrete free of excessive concrete as this

or blockages. may mask a potential fault.

Page 62