Page 73 - Visual Guidance Handbook

P. 73

Let’s all

STEEL MESH BARRIER SYSTEMS get home safely,

every day

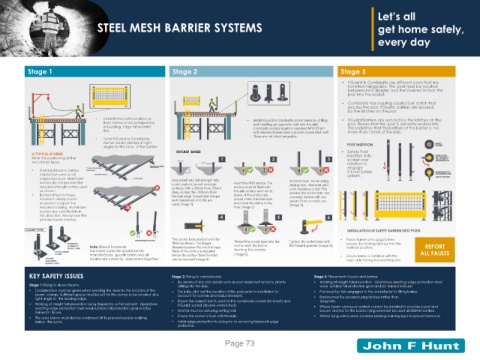

Stage 1 Stage 2 Stage 3

▪ KGuard & Combisafe use different posts that are

not interchangeable. The post must be located

between No2 dimples and then twisted to lock the

post into the socket.

▪ Combisafe has a spring loaded ball catch that

secures the post. KGuard barriers are secured

by the latches on the post.

• Install from a safe location i.e. ▪ Install KGuard or Combisafe socket bases by drilling ▪ KGuard barriers are secured by the latches on the

from below or using Alsipercha and installing an expansion bolt into the slab. post. Ensure that the post is correctly seated into

or Leading Edge fall restraint Combisafe sockets require a standard M16 65mm the socket so that the bottom of the barrier is no

line. bolt whereas KGuard uses a double ended stud bolt. more than 15mm of the slab.

• Install KGuard or Combisafe These are not interchangeable.

Aluma beam clamps at right POST INSERTION EMPTY

angles to the face of the barrier. SOCKET

SOCKET BASES ▪ Safety Post

A TYPICAL SCHEME insertion into INSERTPOST

Note the positioning of the 1 2 3 socket and WITHSPIGOTS

INLINEWITH

two clamp types. 20mm 200mm rotation to SINGLEINDENT

PRIMARYALUMINIUM engage

BEAMCLAMP

• Standard beam clamps STANDARD ALUMINIUM 70mm K-Lock Safety

BEAM CLAMP

cannot be used on all SECONDARYBEAM system. ROTATE POSTTO

ACTIVATEK-LOCK

edges because aluminium PRIMARYBEAM Only install into full strength fully SAFETY SYSTEM

beams do not provide the cured, mature, sound concrete Insert the M16 anchor. The Anchors must be set using

required strength when used surfaces. Drill a 20mm hole, 70mm anchor must sit flush with setting tool. Hammer until

as shown. the slab surface and not sit solid resistance is felt. This

• Barriers fitted to these deep no less than 200mm from above. If the anchor sits secures the anchor into the

the slab edge. Ensure that sharpe,

incorrect clamp points well maintained drill bits are proud, check the hole sizes concrete. Anchor will not

would not support the used [image 1]. and check for debris in the secure if not correctly set

[image 3].

required loading. Aluminium hole [image 2].

beams are very flexible in

this direction. Always use the 4 5 6

primary beam clamps.

CLAMP TYPES INSTALLATION OF SAFETY BARRIER INTO POSTS

INSUFFICIENTSTRENGTH The socket base studs should be Thread the socket base into the Tighten the socket base with ▪ Place Barrier onto spigots then

STANDARD fitted as shown. The longer secure by locking latches into the

ALUMINIUM Note: Ensure formwork threated portion fits into the base. anchor until the foot is the KGuard spanner [image 6]. vertical position. REPORT

BEAM CLAMP has been correctly assembled to touching the concrete

ALUMA BEAMS Note: If the anchor is installed ALL FAULTS

CLAMP manufactures specification and all below the surface then the stud [image5]. ▪ Ensure Barrier is installed with the

PRIMARY beams are correctly assembled together. can be reversed [image 4]. logo side facing toward the posts.

ALUMINIUM

BEAMS CLAMP

KEY SAFETY ISSUES Stage 2: Fixing to concreteslab Stage 3: Placement of posts andbarriers

▪ Be aware of any slab details such as post-tensioned tendons prior to ▪ Working at Height-fall prevention - Operatives erecting edge protection must

Stage 1: Fixing to Aluma Beams drilling into the slab. wear suitable fall protection gear and be trained in itsuse.

▪ Consideration must be given when erecting the deck to the location of the ▪ On slabs, plot out the location of the posts prior to installation to ▪ Post must be fully engaged to the socket prior to fitting barrier.

beam clamps. Sufficient space must be left for the clamp to be located at a account for corners and radius elements. ▪ Barriers must be secured using latches rather than

right angle to the leading edge.

▪ Working at Height-fall prevention using Alsipercha or Fall restraint - Operatives ▪ Ensure the correct bolt is used for the combisafe socket (M16 bolt) and tying wire.

KGuard socket (double ended stud).

erecting edge protection must wear suitable fall protection gear and be ▪ Where beam clamps or sockets cannot be installed to provide a post and

trained in its use. ▪ Anchor must be set using setting tool. secure anchor for the barrier, tying wire must be used at 300mmcentres.

▪ The area below must also be cordoned off to prevent people walking ▪ Ensure the socket is flush with theslab. ▪ Where tying wire is used, consider placing warning signs to preventremoval.

below the works. ▪ Install edge protection to slab prior to removing falsework edge

protection.

Page 73